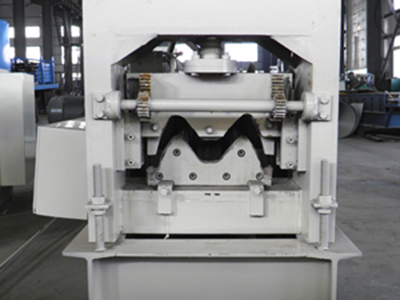

Highway Guardrail Roll Forming Machine

Major Parts

This highway guardrail roll forming machine is made up of a decoiler, a flattening device, punching equipment, roll forming system, cutting equipment, hydraulic system, controlling system and supporter.

Working Process

Raw material follows the following work process with our highway guardrail roll forming machine:

Decoiling →Active feeding→Coil strip flattening→ Punching forhorizontal hole → Punching for vertical hole → Roll forming → Cut to length →Packaging(manual)

| Total Motor Power | 28.2kw |

| Main Motor Power | 15kw |

| Hydraulic Power | 11kw |

| Flattening Power | 2.2kw |

| Forming Speed | 600-800mm/min |

| Forming Roller Material | 45#steel, quenching treatment |

| Number of Roll Stand | 14 |

| Material of Cutting Blade | 12CrMo, quenching treatment |

| Control System | PLC |

| Thickness of Sheet | 2.5mm-3.2mm |

| Width of Sheet | 483mm |

| Length of Sheet | 6000mm |

| Inside Diameter of Coil | 508mm/610mm |

| Outside Diameter of Coil | 1500mm |

Brief Introduction

The highway guardrail roll forming machine is equipped with the uncoiler with chassis, flattening equipment, punching device, roll forming system, cutting device, hydraulic system, controlling system, supporter and other parts.

We are a highway guardrail roll forming machine manufacturer that designs, manufactures and sells colored steel forming equipment that include BH-span Arch Sheet roll forming machine, sandwich panel forming machine, C-shape steel purling machine, highway guardrail roll forming machine and more roll forming machines. With CE certificate, these machines are exported to Romania, Ukraine, India, Iraq, Syria, Egypt, Jordan, Pakistan, and more countries. At Bohai, we are looking forward to working with you!