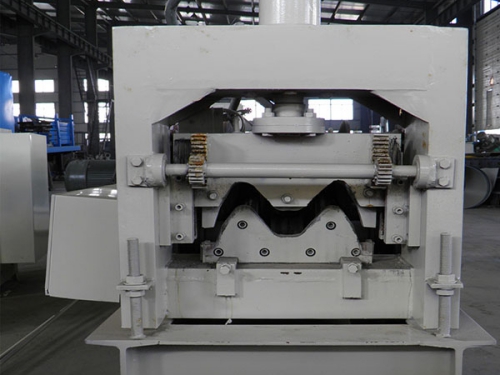

Highway Guardrail Roll Forming Machine

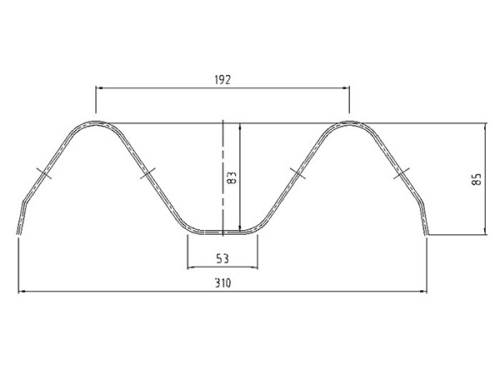

- Rolling material: 2-3mm thickness, inclSpecification of rolling material: Width: 480mm; thickness: 3-4mm; Q235A galvanized steel sheet

- Working speed: 10 -12m/min

- Roller steps: 13 pairs main rollers & 7 pairs flattening rollers

- Material of roller: GCr15 bearing steel, quenched, HRC58℃-62℃

- Material of main shaft: Superior 45# steel, tempered

- Diameter of main shaft: ¢85mm

- Main motor power: 35kw

- Transmission: Double-row chain drive

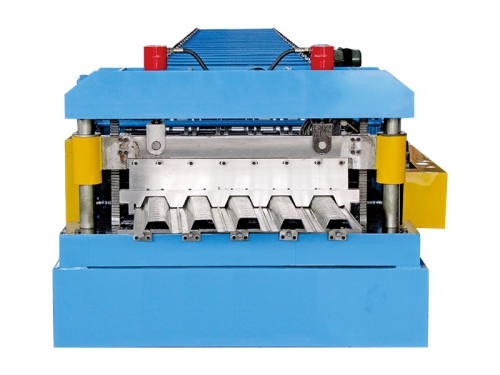

- Structure of forming machine: Wallboard

- Flattening motor power: 2.2kw

- Hydraulic motor power: 11kw, pressure: 20Mpa

- Material of punching and cutting mould: Cr12

- Cutting blade heat-treated: HRC58℃-60℃

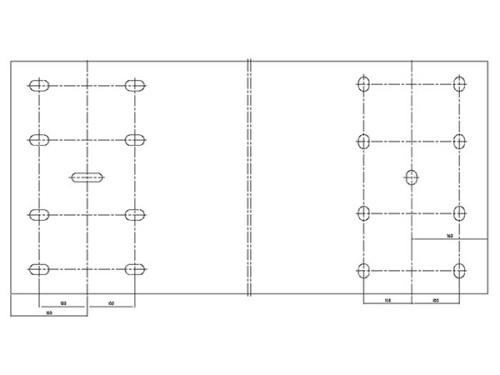

- Punching and cutting way: Adopts hydraulic driving, flat panel punching, cutting after roll forming.

- Electric control system: Whole machine adopts PLC frequency control, cut-to-length error≤±2mm

- Machine dimension: 13500mm×2700mm×1600mm

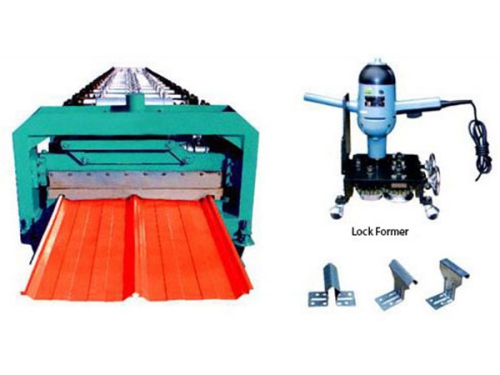

Equipment Configuration

Manual Feeding device (3t capacity), transmission, flattening device, before-punching device (2 sets), main machine and roller (including guide table), cutting (after roll forming) device, hydraulic system, electric control system, run out table, etc.

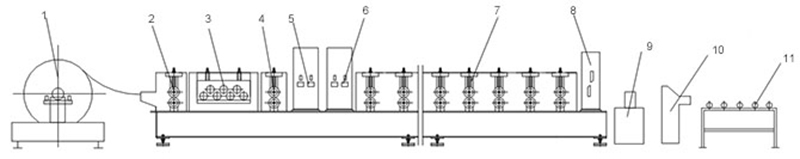

Production Process

Manually uncoiling →Feeding & correcting→ Seven rollers flattening device → Flat panel punching→ Roll forming → Cutting after roll forming → Finished product

- Material Feeding Device

- Pinch Roller

- Leveling Device

- Pinch Roller

- Punching Horizontal Hole

- Punching Vertical Hole

- Forming Machine

- Cutting Machine

- Hydraulic System

- PLC Control System

- Discharging Device

Inquiry

Other Products