Low Speed Steel Barrel Production Line

Established in 2000, Yingkou Bohai Machinery Equipment is an experienced professional steel drum production line manufacturer. Bohai developed metal drum production lines of different production capacities, including high speed, middle speed and low speed, which can satisfy the demands of different barrel making enterprises.

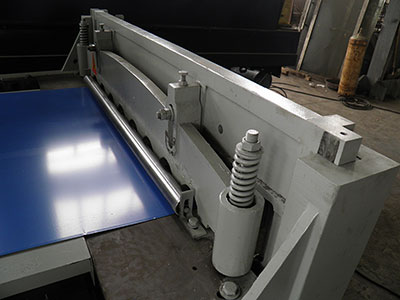

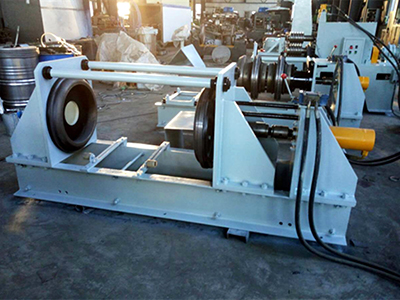

Low speed packaging barrel production line features low investment, easy operation, low maintenance costs, strong adaptability and small size. Possessing the low speed barrel production lines helps to enhance your competitiveness and make you a supplier in chemistry, food, beverage and other fields.

- Detailed technical specifications and raw material consumption parameters for metal barrels are as follows. Bohai can also manufacture special models of low speed oil barrel making lines according to the requirements of barrel making enterprises.

- Low speed manual type metal barrel production line has low production plant requirements and requires 10 employee. The production line is suitable for small sized barrel making enterprises with low labor cost and an annual production capacity of around 100000 pieces. Bohai can design and manufacture customized small and medium-sized steel drum production lines according to the steel drum capacity required by our clients. Bohai not only serves steel drum production line with drum capacity of 180-220L, but also delivers metal barrel production lines with customized capacities.

- Applied sheet: SPCC steel plate or cold-rolled sheet

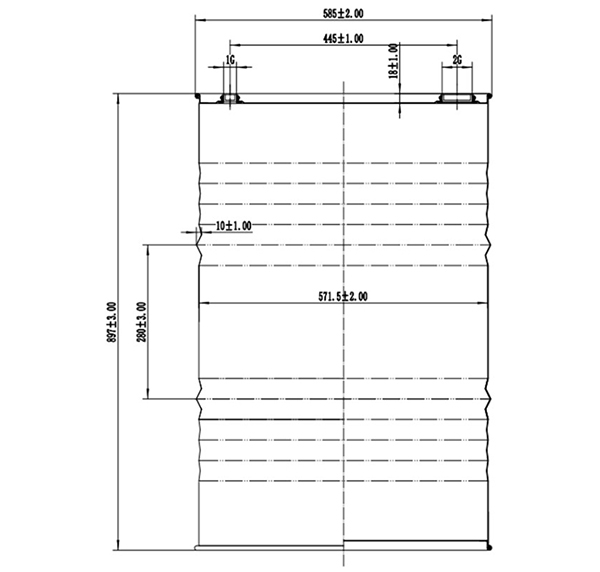

- Drum Inner diameter: 571.5mm

- Drum Outside diameter: 585mm

- Drum height: 897mm

- Material thickness: 0.8-1.2mm

- Numbers of corrugations: 6-10

- Closures: 2 closures

- Top holes: One 3/4 Inch+ one 2 Inch

- Weight: 16-18kg

- Drum capacity: 140L-220L

- Outside painting: Nitro bake paint

- Paint thickness: Minimum 18micron

- Body color: One color or multicolor

| Plate thickness(mm) | Finished drums(pcs/T) | Production capacity(kg/pc) | |

| 1.2 | 41 | 21.5 | |

| 1.0B | Drum cover and bottom 1.2 | 47 | 19 |

| Drum body 1.0 | |||

| 1.0 | 50 | 18 | |

| 0.9B | Drum cover and bottom 1.0 | 54 | 16.8 |

| Drum body 0.9 | |||

| 0.9 | 56 | 16.2 | |

| 0.8 | 63 | 15.9 | |

1. For barrel making enterprises, the program with minimum cost is to purchase steel drum forming machine of steel drum production line. Together with the barrel body sheets, steel barrel top covers, steel drum plugs, cone barrel locking rings and other parts, barrel making enterprises can produce finished steel drums.

2. Drum manufacturing companies can purchase special moulds for asphalt drum, large lid steel drum and conical steel drum to scale up their production and increase the diversity of their drum products.

3. When barrel making companies desire higher steel drum production capacity, they could change the barrel forming machines of steel drum production line one by one. In this process, Bohai will offer professional suggestions to meet barrel making enterprises’ production demands and lower their investment costs at same time, thus to promote our clients’ development.

a.Plugs and Flanges of Steel Barrels

During the production process of steel drums, the parts of the drums will be very dirty and covered with cooling oil. Before the electroplating, the parts must be cleaned and centrifuged to remove extra liquid on the surface. The clean drum parts are prone to corrosion and form red rust rapidly, and which can be prevented with timely electroplating.

b. Electroplating of Steel Drum Components

Plating steel drum parts with a chromate passivation layer can effectively protect zinc from environmental corrosion.

c. Phosphating

Phosphate coatings are often porous, passivation layers can be adopted to prevent corrosion. Phosphated parts should be tightly sealed and packaged in PE bags with silicone gel inside, which can absorb moisture from the packaging.

2. Surface Coating of Steel Drums

Surface coated steel barrels could be used to store hazardous chemicals, food and etc. Two types of coatings are usually adopted on the surface of steel drums, which are phenolic resin coating and epoxy phenolic coating. Each coating has its own unique chemical resistance. Therefore, different coatings needs to match the corresponding steel barrels.