Corrugated Roof Sheet Forming Machine

Bohai has been engaged in the research and manufacture of roll forming machines that include corrugated roof sheet forming machine, 840 corrugated sheet roll forming machine, sandwich panel forming machine , flat sheet bending machine, etc. With more than 20 years of experience in this line, we know how to produce a productive and durable corrugated roof sheet forming machine at a low cost. Please contact us for your corrugated roof sheet forming machine needs.

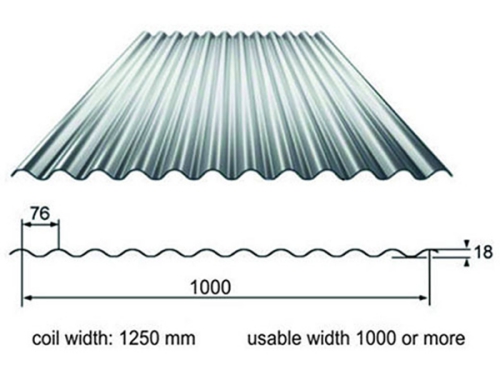

Profile Drawing

- De-coiler: Manual operation, passively de-coiling

- Loading of de-coiler: 5t

- Frame of machine: Welded with 350H beam steel

- Guide feeding way of forming: Side direction roller type

- Forming machine type: Wallboard and chain drive

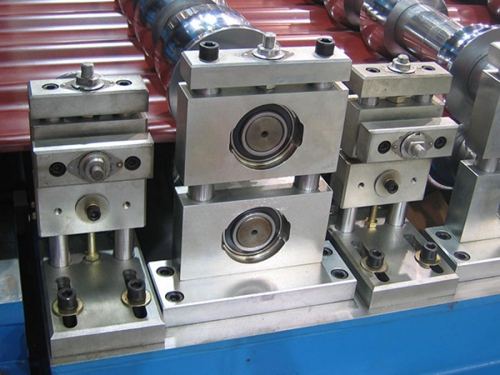

- Diameter of shaft: ¢76mm

- Chain: 16A single row

- Motor power of forming machine: 5.5KW

- Line speed of forming machine: 5-17m/min

- Steps of forming machine: 18

- Roller material: Superior 45# steel forging

- Thickness of chrome plated on roller: 0.05mm

- Hydraulic station motor: 4 KW

- Hydraulic station oil pump: Gear pump

- Cutting way: Cut off after hydraulic shaped

- Cutting blade material: Cr12

- Cutting blade heat treatment: HRC58℃-60℃

- Rolling thickness: 0.4-0.8mm

- Feeding width: 1250mm

- Precision of cut-to-length: ±2mm

- Frequency changer: Panasonic

- Computer adopts PLC: Panasonic

- Dimension of machine: 8.5m×1.6m×0.8m

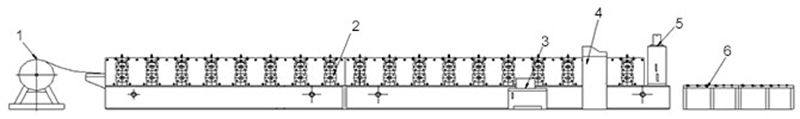

Technological Process

Passively De-coiling → Guiding & Feeding Material → Roll Forming → Cutting-to-length → Output Panel

- Unpowered Material Feeding Device

- Forming Machine

- Hydraulic Tank

- Computer Control Cabinet

- Hydraulic Shear

- Discharging Device

| No. | Item | Qty. |

| 1 | Passive d e-coi ler | 1 piece |

| 2 | Roll forming machine | 1 piece |

| 3 | Hydraulic cutting blade | 1 set |

| 4 | Hydraulic station | 1 piece |

| 5 | Computer control c ounter | 1 piece |

| 6 | Run out table | 3 pieces |

- This corrugated roof sheet forming machine is controlled automatically by superior software to accomplish the management of information.

- In accordance with the international advanced level, this product allows the customized design and manufacture as the users want. We supply complete after sales service for users, as well as the technical support for installation, adjustment and maintenance of the machine.

Our product can be provided to make the sheet in different coil width and height of wave. The profile drawing is available in replying the inquiry of customers.