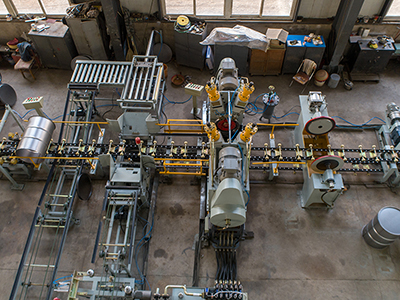

Medium Speed Steel Packing Drums Production Line

Founded in 2000, Bohai is a steel barrel making equipment manufacturing company. With years of experience in steel drum machine manufacturing, the steel drum production lines we produce can be in different types, including professional high speed steel barrel production line, best-selling medium speed steel drum equipment, and low speed packaging steel barrel manufacturing machine. And our metal drums can be of different series, such as closed head 55 gallon steel barrel, open metal drums, bituminous steel barrels, conical metal drums, which the capacity of all series drums ranges from 180L to 220L. The complete range of open head and closed head steel drum production line can be customized for different steel barrel capacity and sizes.

Strong production capacity, smooth operation and high quality of our medium speed packing barrel production line make it popular with barrel making enterprises worldwide and has become the best-selling closed head metal packaging drum production line. The medium speed steel drum making machines are suitable for medium-sized barrel making enterprises, and the steel drums it produced are suitable for various industries such as chemical, petroleum, construction, food, beverage, etc.

- The technical parameters and raw material requirements for commonly used steel barrels are as follows. If you require steel drums of other capacities, Bohai is also ready to supply customized steel drum production lines, as per your request.

- Steel drum production line requires an area of about 3000 square meters, superior manufacturing technique, and rational machinery layout accordance to the plant conditions. With professional technical team and extensive experience, Bohai is fully qualified to offer you application instructions about middle-speed steel drum production lines.

- Applied sheet: SPCC steel plate or cold-rolled sheet

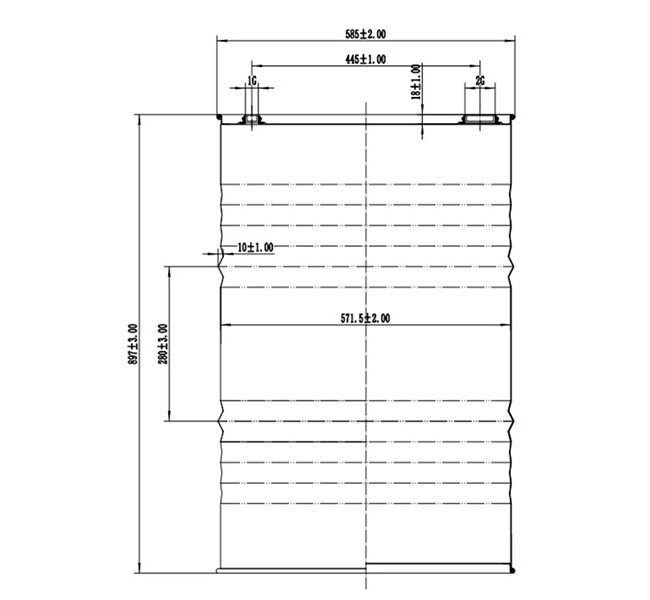

- Drum inside diameter: 571.5mm

- Drum outside diameter: 585mm

- Drum height: 897mm

- Steel thickness: 0.8-1.2mm

- Numbers of corrugations: 6-10

- Closures: 2 closures

- Top holes: One 3/4 Inch + one 2 Inch

- Weight: 16-18kg

- Drum capacity: 140 L-220L

- Outside painting: Nitro bake paint

- Paint thickness: Minimum 18 micron

- Body color: One color or multicolor

| Plate thickness(mm) | Finished drums(pcs/T) | Production capacity(kg/pc) | |

| 1.2 | 41 | 21.5 | |

| 1.0B | Drum cover and bottom 1.2 | 47 | 19 |

| Drum body 1.0 | |||

| 1.0 | 50 | 18 | |

| 0.9B | Drum cover and bottom 1.0 | 54 | 16.8 |

| Drum body 0.9 | |||

| 0.9 | 56 | 16.2 | |

| 0.8 | 63 | 15.9 | |

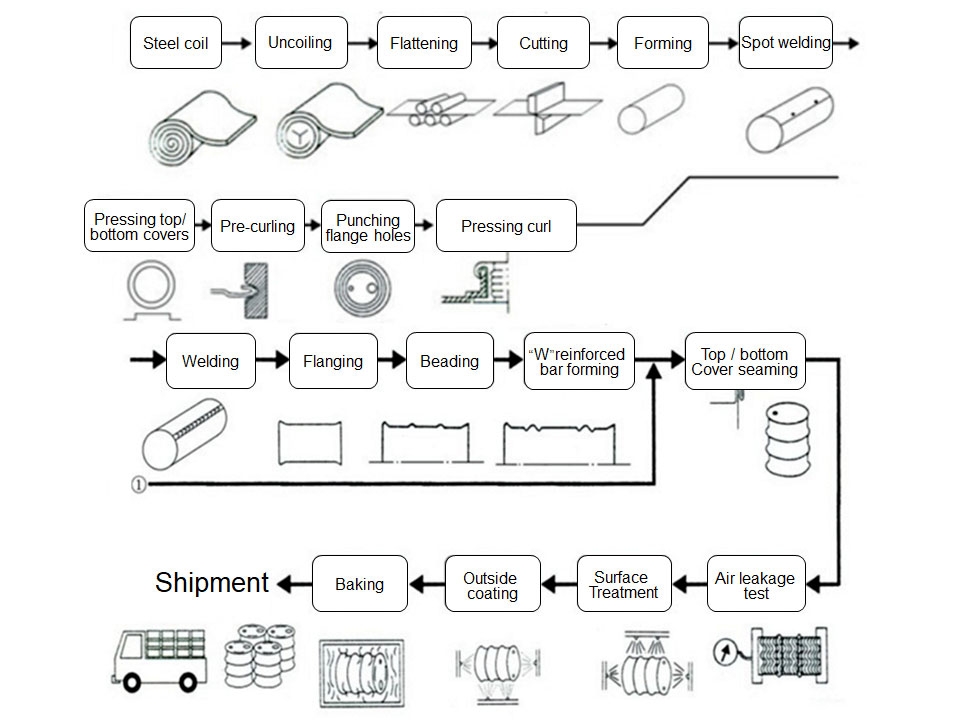

- Equipment of Front Section

There is a range of advanced equipment outfitted in this part, such as decoiler, hydraulic supporter, hydraulic up-coiler device, flattening rectifying deviation device, and cutting machine. After the steel sheet coil is decoiled, it will be flattened, sized and cut into the required dimension of drum, ready for next procedures. - Middle Section Devices

The middle section devices include the circle rolling machine, spot and seam welder, edging machine, beading machine, W rib corrugating machine, edge-curling machine and leakage checking equipment. In this part, users can select the edging machine with beading machine or integrated machine of edging and beading. Steel drum will be formed from steel sheet in this section. - Structure of Last Section of Line

The last section of the medium-speed steel drum making machine is set with degreasing and phosphorizing room, washing and drying room, painting room, drying room after painting and coolers.

1. Bohai manufactures semi-finished steel barrels, including barrel bottoms, barrel tops, barrel body sheets, steel drum plugs, steel drum hoops, etc. For barrel making enterprises, they only need to purchase middle-section machinery of medium-speed steel drum production line, which is mainly designed for the forming process of steel packaging drums. With secondary processing of semi-finished products, steel barrels can be produced. In this way, the satisfying production capacity, the lowered requirements towards manufacturing plants, and minimized cost can be ensured.

2. With medium-speed steel drum production line, barrel making enterprises can produce more barrel types, such as open head steel barrels, bituminous metal drums, conical steel barrels, only special manufacturing equipment for other types of steel drums needs to be added.

3. With customized manufacturing requirements and purchasing budgets, Bohai helps design steel drum production line and deliver rational configuration for barrel making enterprises.

- Poor Print Glossiness and Brightness on steel drum.

Cause: Low varnish viscosity, thin coating and uneven surface of metal sheets

Solution: Properly increase the varnish viscosity and coating weight, and add as little diluent as possible; Filter varnish of heat transfer printing equipment during steel drum production; Clean coating machine when replacing the varnish to avoid the mixing of different coatings. - Printing Blurry and Not Bright Enough

Cause: Low color density of images and text on the original paper leads to poor printing quality of steel barrels; The temperature and pressure of the heat transfer equipment fail to set properly.

Solution: Deepen the color of images and text before steel barrel printing; Increase the ink amount when printing the base paper to make the color as bright as possible; Set the optimal temperature, pressure, and time of heat transfer printing equipment during the sampling process. - Low Hardness and Poor Adhesion of the Coating Layer

Cause: Low hardness of the printing ink, metal plate coating, and varnish on the steel drum may cause scratches and exposure of base coat; Poor viscosity, fluidity, and heat resistance of the ink, low viscosity of the varnish, thin coating, or poor adhesion of the steel drum metal sheet, may cause poor adhesion, low hardness, failure to paint, and the precipitation of pigment; The temperature and pressure of the heat transfer equipment fail to set properly.

Solution: Strictly control the drying degree of the ink and coating/varnish of the heat transfer printing equipment, appropriately increase the viscosity of the varnish on the steel drum metal sheet, and increase the coating weight; The flowability, water resistance, and color rendering of ink and coatings/varnish all play important roles in the quality of steel drum metal printing. Polishing increases the glossiness of the steel barrel presswork surface and the adhesion between the metal sheet and the ink layer, thus to protect the steel barrel printing surface, improve the hardness, firmness, and corrosion resistance of the steel barrel printing surface; The selection of coating/varnish is very important; Strictly control the amount of additives in ink and coatings, and fully utilize the strong adhesion of the primer coating; Set the optimal temperature, pressure, and time of heat transfer printing equipment during the sampling process.