Steel Bitumen Barrel Production Line

Bohai has been dedicated to providing our customers with our top-quality barrel making packing equipment of different series and capacities, and contributing to barrel making industry since its establishment in 2000. The steel drum production lines include bitumen barrels, closed head metal drums, open head steel drums, and conical barrels. Bohai has steel drum manufacturing lines with an output of 8 barrels per minute, steel drum making machine lines with an output of 5 drums per minute, and steel drums production lines with an output of 2 steel drums per minute.

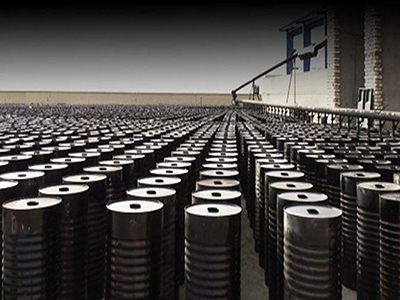

Steel bitumen barrel production line can be combined with regular drum roll forming machinery to become barrel roll forming line, which can produce bituminous steel drums, open head barrels, and closed head 55 gallon barrels. Fully utilizing the shared equipment in the steel drum production line ensures an improved efficiency of the barrel making enterprise. Bituminous steel drum production line is perfect choice for both bituminous drum manufacturing enterprises and large drum forming machine equipment enterprises.

Asphalt barrels, as disposable ones, are exclusively designed for the storage of asphalt. Due to the special nature of raw materials, the thickness of bitumen drum generally ranges from 0.6 to 0.8mm, which is relatively thinner than other drums. Therefore, more reinforcing ribs are adopted on drum body. Steel bitumen barrel production line consists of the front, middle and rear section, and is composed of dozens of equipment, which requires 2-10 employees. The asphalt barrel production line covers an area of about 2500 square meters, with a stacking area of about 1000 square meters. Bohai, with extensive experience and expertise, is fully capable to deliver technical assistance and help our customers’ production line layout according to the conditions of the operating site, thus to save the area of work place and ensure the smooth operation of production lines.

1. Bohai offers the barrel body, drum top and bottom, steel drum plugs, and other semi-finished barrel parts. Due to their small size, the space efficiency and easy transportation can be well ensured. Barrel making enterprises only need to purchase bitumen barrel forming machines for the further processing of barrel parts.

2. Constructed on a basis of closed head steel drum production line, when equipped with asphalt galvanized drum, open metal drum, conical metal drum special making machinery, barrel making enterprises can possess different barrel making production lines. It minimizes the investment costs, maximizes the value of steel barrel production line, and highly improves the production capacity of barrel making enterprises.

3. With customized purchasing budgets, Bohai helps to design steel drum production line and deliver rational configuration for barrel making enterprises.

Galvanized steel plate, coated with a layer of zinc, is always used as raw material in the production of steel drums. When seam welder, one of the machines in steel drums production line, is working, it often damages the zinc coating at the seam line of the steel barrel. Zinc coating is corrosion resistant and aesthetic, therefore, zinc touch up or repair at weld line is required for longer service life of steel barrels. At present, the zinc touch up or repair adopted on barrel making industry can be divided into three types:

- Hot-dipped Tinning: First clean the surface of weld line on steel barrel body with soldering flux (commonly with zinc chloride solution), then heat the weld line, and finally apply molten tin to the weld line on the steel barrel.

- Aluminum Paste Spraying: After polishing the oxide layer at the weld line of the steel drum, spray specific aluminum paste for galvanized steel barrels.

- Zinc Spraying: It uses arc spray equipment, specially designed for galvanized steel barrels, which is the best zinc replenishment method.