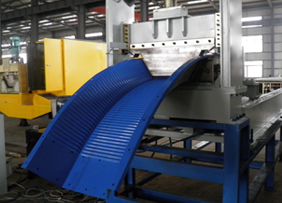

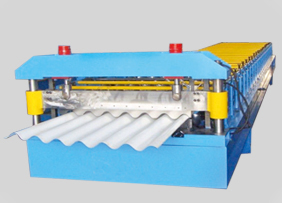

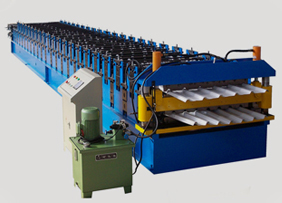

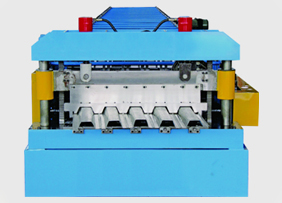

Yingkou Bohai Machinery Equipment Manufacture Co., Ltd. was founded in 2000. Spanning an area of 15000 m², we have more than 100 employees including 10 senior engineers. We have an excellent R&D team and complete management system. Our main products are steel drum production line, arch roof sheet roll forming machine available with many moulds, glazed tile roll forming machine, double layer roll forming machine, corrugated roof sheet roll forming machine, etc. All of our machines are certified by ISO9001:2008 standard and CE. We also have our own Trademark and Patents. Superior quality with reasonable prices wins worldwide reputation.